Back home and back to work.

I hopefully plan to get the engine and gearbox in this time home but then that was the plan last time so fingers crossed.

Lots of things bought this time and a few changes to my plans, the elbow arrived to fit the oil pressure sender under the fuel pump which I thought at the time would solve the problem I had of it hitting against the pump. I tried it in position this morning and although it fits it looks cramped and wrong so I have found an alternative which is a sandwich adapter, to fit this you remove the oil filter and screw this in its place then refit the filter sandwiching it between the filter and the block. The sender then screws into the side, much neater.

The Distributor cap and Rotor Arm arrived and although they are not original Bosch parts they are still good quality and went straight on.

I was also advised that it is good practice when replacing a clutch to also replace the Spigot or Pilot bearing that takes the end of the input shaft, at only around £10 inc p+p I thought I'd best get one.

I have also ordered a clutch kit, the old clutch gives the size at 242mm which was not to difficult to find although most I have looked at are sized at 241 or 240mm for the Granada mk2 2.8 but a search on Euro Car Parts came up with it straight away. I gave the part number to my local autoparts and he beat the price. £102

I have also won on eBay a timing light in preparation for the eventual start up, the light is by a company called C Z Sincro of which I had never heard of until I gave the name a search on Google and found out that they also make timing lights for Snap on so I put a bid in and got it for £13 plus p+p its only a basic one but it will do the job.

For a while now I have been thinking about modifying the reach of the gearstick by fitting a Remote gear link extension, this will have 2 advantage mainly that I will not have to stretch to reach the gearstick and that it will free up space in front of the radio. The work involved is pretty straight forward and will require cutting a new hole into the tunnel and blanking off the old one, bolting the extension onto the gearbox then just fitting the stick. I would imagine that after all of these years I will not be the first to fit one of these extensions, the main problem I can see is that the extension is fully exposed to all of the weather and dust getting into the sliding parts. I have not received it yet but shall look into modifying it to fit rubber boots over the sliding parts and pack with grease. Will soon see, it cost £55 plus p+p so I hope it works.

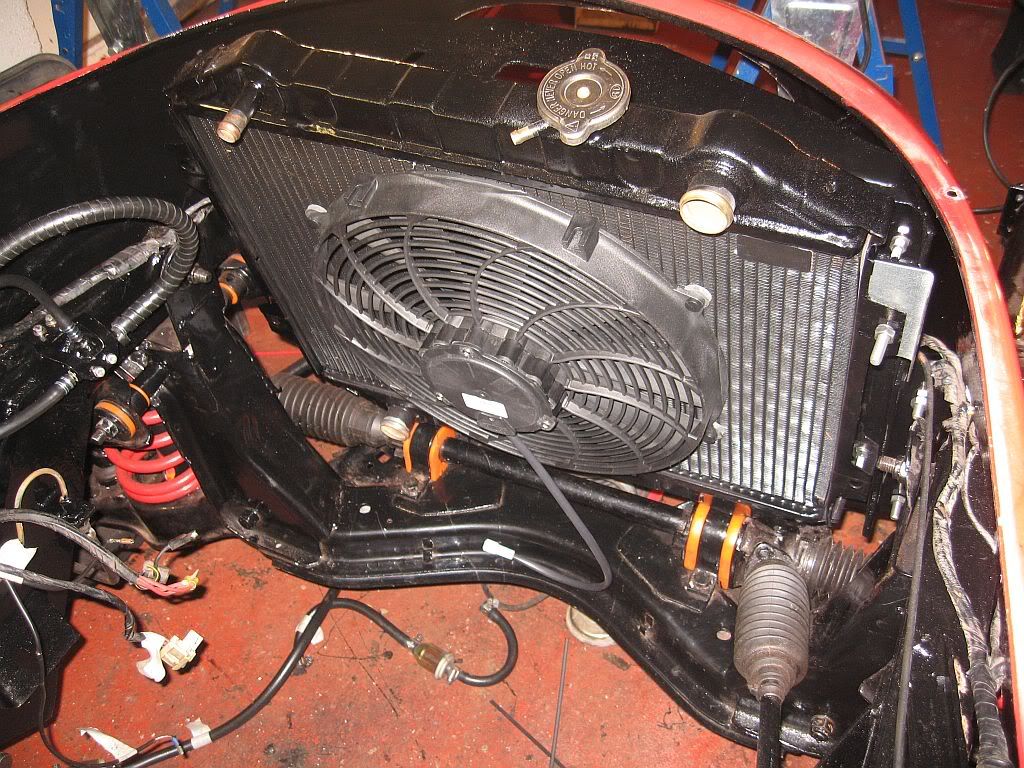

I got back in the engine bay today and started with the radiator and fan, the fitting kit was very good and the quick fit pins went straight through the fins and pulled up nice and tight. The fan is the 14" model and fits perfect covering around 70% of the area.

I bolted the radiator to the frame and have fitted it to the car, I may have to remove it again when I refit the engine but needed it in place to make the bracket for the expansion bottle modification.

I hope to make a pressurized system which depends upon me finding a blanking cap for the radiator of which I have not found as yet, if I can't find one then I shall just fit 2 pressure caps.

The bottle is a plastic one although I have a brass one I want to see the level until I have it set up and working. I have used one of the old cowling bolt holes to connect the new bracket which I made this morning out of a piece of angle iron and a square of aluminum riveted on. I don't know if I have the height correct as I have no reference to work from so I have made the bracket hole slotted so as to raise it if necessary.

When this was done I got on with the fuel pipes, I had removed and painted the fuel return valve which was a bit rusty.

All cleaned and painted, then a simple job to refit the valve and cut the new nitrile pipe to fit, the filter looks good but will have to be lightly coated in silicone grease as it won't last 5 minutes with the salt on our roads.

A bit difficult to make out with the black pipe on black background

I have also bought a tin of black engine enamel, although I had sprayed the heads with 4 coats of VHT black paint I was still not happy with the finish. Now with a coat of black enamel it looks as good as the block and as its high temp paint I shall also use it on the exhaust manifolds.

The rocker covers also need a fair bit of work before fitting, firstly I have given them a good cleaning as there was a lot of old oil residue staining the inside and dried flaky oil under the deflector plates.

All nice and clean now, I shall sand them down and paint them red and highlight the letters and lines in black. The main problem is that these rockers don't have a breather hole to connect to the carb for the removal of the crank oil vapour's.

You can see the difference between the two, the deflector plate on the alloy rocker is situated under the pin which if drilled through there makes the hose to short.

I have a couple of options here, either to:-

Not to bother fitting the hose but drilling through where the pin and deflector plate is and fitting a K&N crankcase breather filter which will require the blanking of the carb plate.

or

Drilling through in the same place and fitting the hose which will make it around 50mm short then cutting the hose and fitting a piece in.

or

Drilling a hole in the same place as the original is and modifying the deflector plate underneath, which will also mean cutting out a section of the cast lines to get the rubber grommet to fit flush.

Yes confusing ain't it.

Don't know what to do yet, but will decide over night.

See ya Paul

No comments:

Post a Comment