A good day today I really enjoyed working on the engine, I do this for a living but its different when its at work and a fuel pump requires a crane to lift it and an injector has to be carried on your shoulder.

Also a lesson to be learn't for those out there who are somewhat reluctant to get your car serviced, strangely I was watching a you tube video I came across about not changing your oil regularly and guess what I found when I had a look at mine.

I started out this morning having to go and buy some more rotary wire brushes as I wore mine out yesterday and also payed a visit to the nut & bolt man at the flea market and stocked up on stainless nuts & bolts, got quite a collection now. I carried on cleaning the engine starting with the air inlet manifold and had this complete when I thought I'd get the rockers of and have a look inside, this is what I found.

The dreaded black sludge; I guess this car has had either no oil change ever or its been a long time ago as it only has 35,000 miles on it, maybe 10 15 years ago when the last owner was keen.

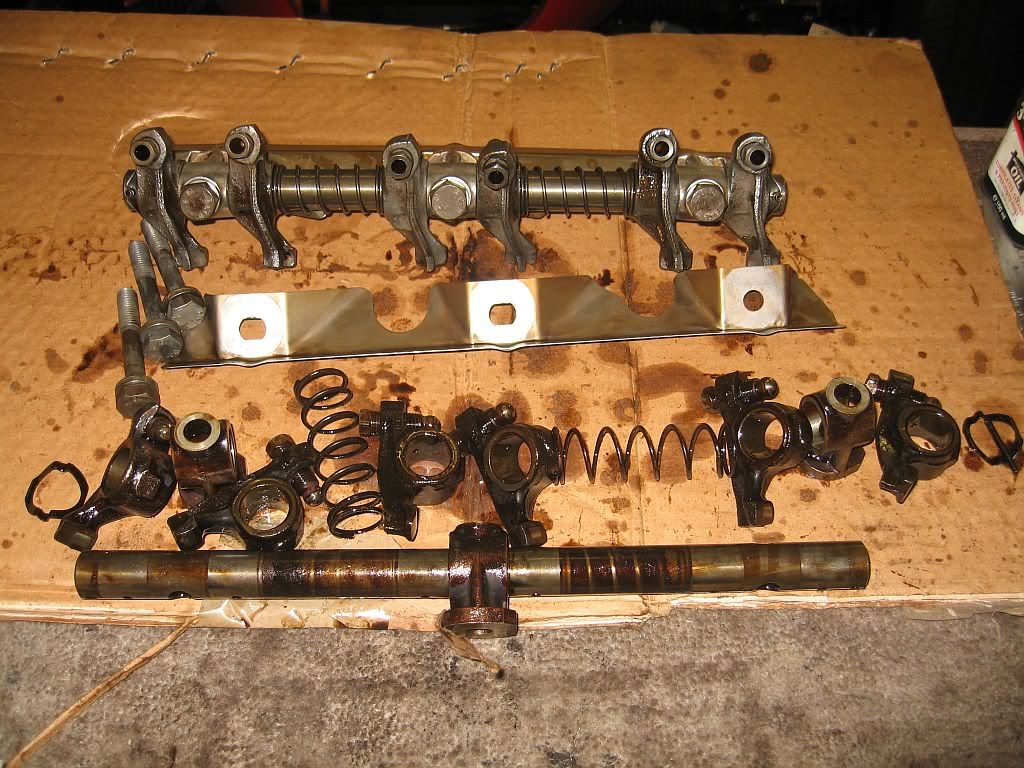

There is no way I would ever leave it like this so its back to my original plan of a full strip down and clean, it also leads me to wonder whether the last owner was diligent about the unleaded additive so I am going to remove a valve or two and check the seats. So where to start, rockers first so off they, came and got a good cleaning before putting safely away.

I stripped the first one and cleaned with white spirit and it came up nice in comparison the the other.

This one got the same treatment.

All clean

These were easy enough to strip and clean, I left the centre hold down in position and cleaned around as the Granada manual says that a groove is cut at the end and should face down for the oil ways, well there is no groove on mine. Maybe I have a later model, think I'll bin the Granada book and stick to the Capri, anyway I left the centre hold down in position so as not to lose the oil way position.

I next started on the heads working from the centre out I broke the torque on the head bolts and removed all of these, I then removed the air manifold bolts and nuts and was ready to lift. One problem that I had is that the engine stand is bolted to the bell housing holes, which is the only place it can go, unfortunately there are 3 clutch positioning pins that stick out of the fly wheel which prevent the engine from turning more than a few degrees either way as they hit the stand off. To remove the distributor I really should have have unit #1 at tdc but I can't turn the engine to get it there, the other problem I have is that the timing plate with the engine markings on is so badly rusted that there are no readings (just bought a used one from eBay) so it would be difficult to find where #1 tdc is. So I had to remove the distributor without it being in the correct position which I imagine will cause me all sorts of problems later on.

Once all the bolts were removed I took a large screwdriver to the corners of the heads and lightly levered until the seal was broken

The air manifold lifted straight off

The gasket was well stuck but a large knife slide around lifted it off.

Lots of sludge in the corners.The heads came of next

On close inspection its not just black oil deposits but the waterways are also partially blocked and I bet the oil ways aren't much better.

So a lot of work ahead to get this mess cleaned up and a lot of learning, I shall buy a spring compressor tomorrow to check on the exhaust valves and see if there is any damage, I have a full gasket set already bought so no problem there. The main problem is getting the engine to turn, I may have to get the crane out again to take the weight while I fit spacers as I doubt I'll be able to remove the pins inserted in the flywheel but I'll give it ago.

See ya

Paul

No comments:

Post a Comment