Well, I have been rather busy lately but unfortunately it has not been much on the car, mainly because I have been waiting for the head to arrive and yesterday I got an email from the Car Clinic to say it is ready. I am having it unleaded and it also requires the valve guides renewing and a skim, bit of a problem now as I am back to work at 0230 in the morning so a little to late, so I have arranged for them to hold it until I return.

I have been getting a few small jobs done on the car but my time has mainly been spent on the computer studying courses for my new job.

Yes time to move on, so last Wednesday I went for an interview in Great Yarmouth on the Norfolk coast, bit of a journey as I set out at 0615 and got home at 0130 the next day rather tired but successful so this is my last trip on the DFDS Dover ferry service.

The ships sails to its location, positions itself using its dynamic positioning system then;

Drops its legs and lifts itself out of the water to give a stable platform with no rocking from the waves.

It can then build or repair the wind turbines or oil gas platforms.

Pretty amazing ships, so I have been rather busy studying every day.

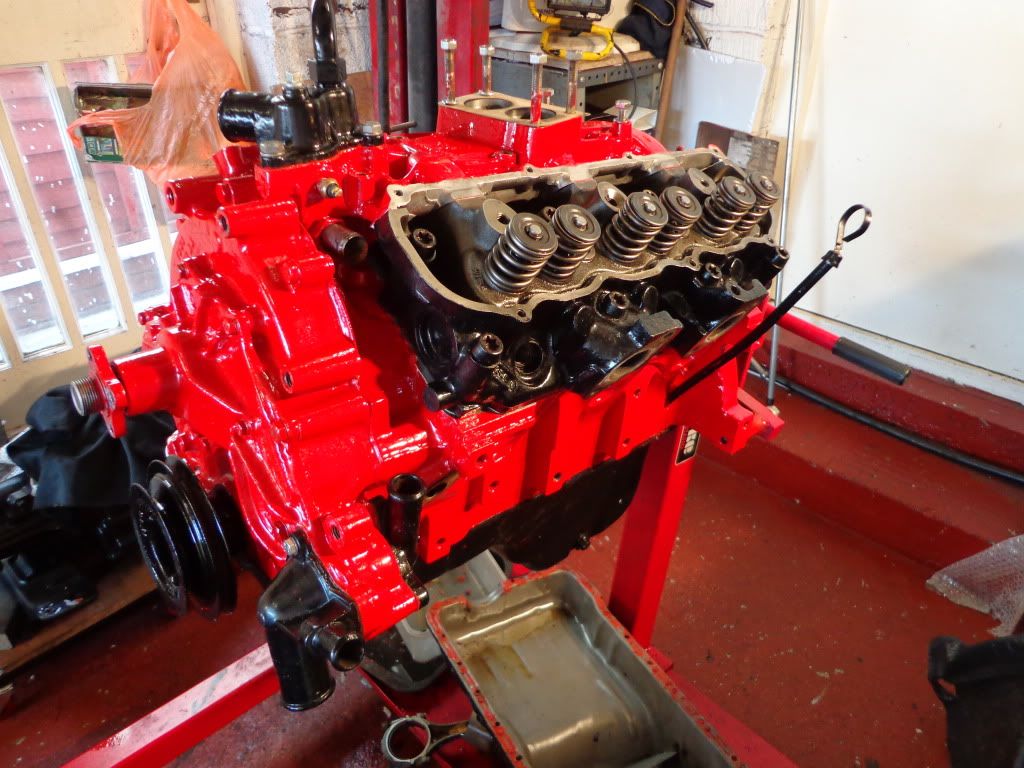

One thing that did arrive was my new engine paint, the same company as the black paint for the heads and paints on nice and smooth with great colour.

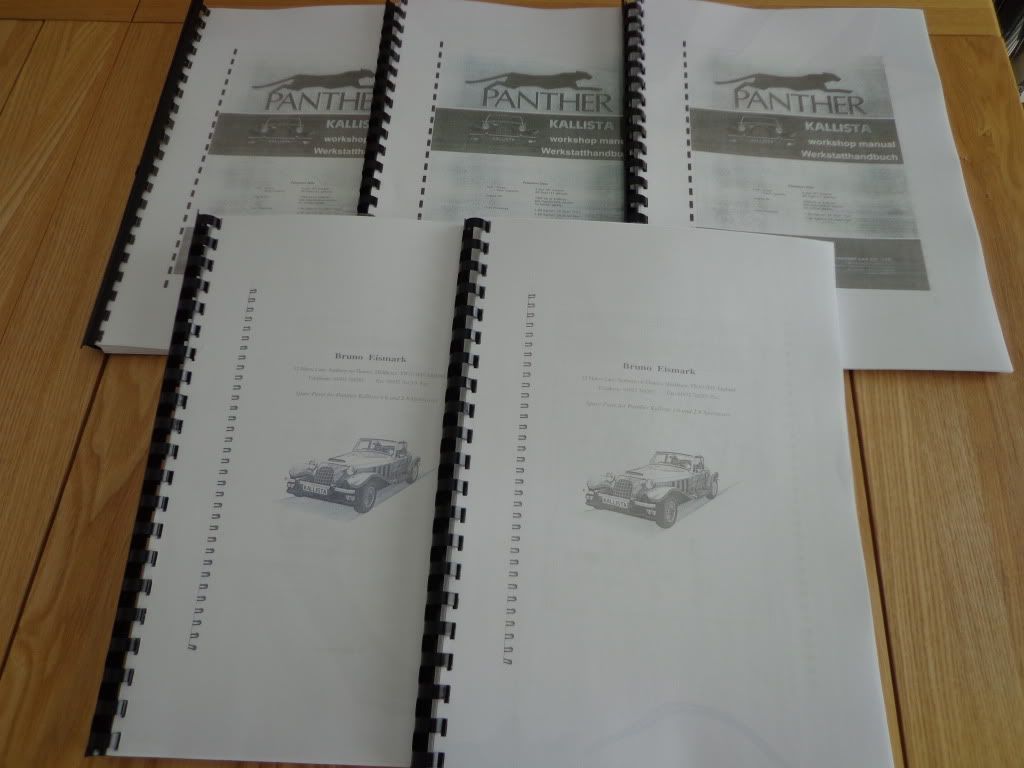

I have at last got hold of the Bruno spares catalog and just as importantly the Work manual for the Kallista, up until now I have been working blind but hopefully now I should get a few thing right. I was told by Bruno that the spares cataogue was on the disc supplied by Geli from the Panther club so I sent her an email and quick as a flash the disc arrived. Great disc packed with info, photos and more importantly the spares and workshop manual.

All printed and bound with well over 350 pages.

While everything is apart again I thought I would try to explain what went wrong with the gearbox extention.

I thought, as other people who have been in contact with me thought; that because the extension is designed for a type 9 gearbox that it would fit and work with any Ford setup, well it don't.

It all has to do with the position of the knuckle joint, if the spline'd connection tube was a few inches longer and the knuckle set back then no problem but the design of the Panther drive shaft is all wrong for this extension, again a picture speaks etc!

You can see that the position of the knuckle is perfect to hit on every pass.

Drops its legs and lifts itself out of the water to give a stable platform with no rocking from the waves.

It can then build or repair the wind turbines or oil gas platforms.

Pretty amazing ships, so I have been rather busy studying every day.

One thing that did arrive was my new engine paint, the same company as the black paint for the heads and paints on nice and smooth with great colour.

I have at last got hold of the Bruno spares catalog and just as importantly the Work manual for the Kallista, up until now I have been working blind but hopefully now I should get a few thing right. I was told by Bruno that the spares cataogue was on the disc supplied by Geli from the Panther club so I sent her an email and quick as a flash the disc arrived. Great disc packed with info, photos and more importantly the spares and workshop manual.

All printed and bound with well over 350 pages.

While everything is apart again I thought I would try to explain what went wrong with the gearbox extention.

I thought, as other people who have been in contact with me thought; that because the extension is designed for a type 9 gearbox that it would fit and work with any Ford setup, well it don't.

It all has to do with the position of the knuckle joint, if the spline'd connection tube was a few inches longer and the knuckle set back then no problem but the design of the Panther drive shaft is all wrong for this extension, again a picture speaks etc!

You can see that the position of the knuckle is perfect to hit on every pass.

I have even made a little video to show you.

So to make it work requires a re-design of the drive shaft to set the knuckle back which even though I really wanted the space in front of the gearstick I don't think the expense is worth it.

Well not a lot accomplished on the car, the damage to the head really set me back both financially around £400, and time wise.

I have just had my SORN reminder and have re-sorned the car, so that is 1 year I have been working on the car but due to my work patterns that is really only 6 months.

So next time home I will hopefully be able to get the head on and engine /gearbox fitted before I go on holiday and start my new job.

see ya Paul

Well not a lot accomplished on the car, the damage to the head really set me back both financially around £400, and time wise.

I have just had my SORN reminder and have re-sorned the car, so that is 1 year I have been working on the car but due to my work patterns that is really only 6 months.

So next time home I will hopefully be able to get the head on and engine /gearbox fitted before I go on holiday and start my new job.

see ya Paul

Simple trick to cut your power bill up to 75%:

ReplyDeleteWant to know how to easily produce all of the renewable energy you could ever want right at home?

And you will be able to make your home completely immune from power outages, blackouts, and energy grid outages…

so even if everyone else in your area (or even the whole country) loses power…you won’t.

OUR GUIDE: DIY HOME ENERGY